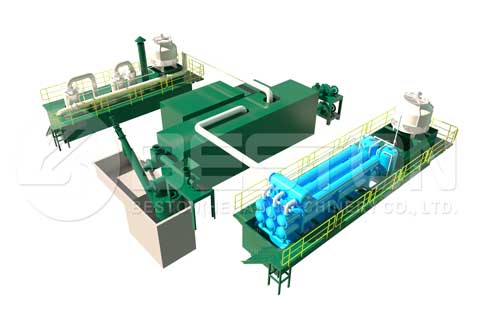

A continuous plastic pyrolysis plant is an automatic plastic pyrolysis plant and it is a great option because it’s a way to make use of all of that waste plastic that would end up making it to the landfill. You don’t want that waste to end up there, and it would be nice to explore more about how the waste plastic can actually turn into useful products. You’re talking about carbon black, pyrolysis oil and hydrocarbon gas. Perhaps it’s the superior way of addressing the recycling of waste at your facility.

Some businesses recycle their plastic to continuously develop new products. They are dealing in plastics, and they can turn around and use the plastic for other reasons. But not all businesses are recycling products to make new ones. (To learn more information about the plastic pyrolysis machine manufacturers, you can visit the website of Beston Group.)They just have waste plastic that doesn’t need to make it to the environment. So would a pyrolysis plant in many cases be the best choice for many of the companies out there?

You would think that they would be a great idea because there are many companies who have tons of waste plastic, and they don’t know what to do with it all things considered. That may be the case, but a pyrolysis plant can continuously get rid of all of that waste 24/7. The plant is easy to run, and companies can explore their options in terms of the resources that are produced from such an operation. Refer to https://bestonmalaysia.com/plastic-pyrolysis-plant/ for more details.

If you are thinking about getting one of these pyrolysis plants, you might be wondering if you’re going to have to pay much money to keep it up and running. You see, a pyrolysis plant is actually supposed to be a profitable venture. Part of the pyrolysis oil that is produced from the recycling of plastics can actually fuel the machine. Therefore, you are consistently able to count on the machine practically running itself.

The controls are supposed to be easy, too, so it’s not like a bunch of manpower is required. While a pyrolysis machine can be bigger, faster and stronger, that doesn’t have much to do with the fact that it requires tons of employees to keep it going. It’s about the power of the machine itself, the user-friendly controls, and the fact that it can turn a lot of plastic waste into desirable resources.

If you really do not want a continuous one, we suggest a small scale one for you, which you can find in https://bestonmalaysia.com/small-scale-pyrolysis-equipment/.

If you’re not convinced as of this very moment, you can take a look at what you can do with those resources. There are options you have, including selling some of them. You may know some companies in your area that could make use of carbon black. Or perhaps you have a need for most of the resources yourself. You’re going to be finding out soon enough as you take a closer look at what you get when you have a pyrolysis plant in place. You can also follow us on FaceBook to get more details.

The plastics pyrolysis process is really interesting to many business owners out there, and you can see why. Now you’re going to be able to take a closer look at what it’s going to mean for your business. Pretty soon, you will be getting valuable resources from the waste plastic you have at your facility.