The increasing emphasis on sustainability and resource efficiency has highlighted the potential of pyrolysis technology in transforming waste biomass into valuable charcoal. This process not only addresses waste management issues but also contributes to sustainable energy solutions. By examining the transformation from various types of biomass, including wood processing waste, food processing waste, and agriculture waste, we can appreciate the intricate role of pyrolysis in modern waste-to-energy systems.

Understanding Pyrolysis Technology

Pyrolysis is a thermochemical decomposition process that occurs in the absence of oxygen. This process involves heating biomass to high temperatures, typically between 350°C and 700°C, which results in the breakdown of organic material into gaseous, liquid, and solid byproducts. The solid byproduct, known as biochar or charcoal, is a carbon-rich material that can be utilized for various applications.

The efficiency of pyrolysis technology depends on several factors, including the type of biomass used, the pyrolysis conditions, and the design of biomass pyrolysis plant. The versatility of this technology makes it suitable for converting a wide range of biomass feedstocks into valuable products.

Food Processing Waste and Its Utilization

Food processing waste encompasses a variety of organic materials generated during the production, processing, and packaging of food. This includes fruit and vegetable peels, shells, and other organic residues. Traditionally, food processing waste is discarded or composted, but pyrolysis offers a more efficient method of utilization.

The pyrolysis of food processing waste results in the production of biochar, which has applications beyond mere waste management. Biochar derived from food processing waste can improve soil health by enhancing soil structure, water retention, and nutrient availability. This not only provides a sustainable way to handle food waste but also contributes to agricultural productivity.

Wood Processing Waste and Its Transformation

Wood processing waste is a significant byproduct of the timber industry. It includes sawdust, wood chips, and shavings that result from the cutting, shaping, and milling of wood. Traditional disposal methods for wood processing waste often involve landfilling or incineration, both of which have environmental drawbacks.

The conversion of wood processing waste into charcoal via pyrolysis presents a more sustainable alternative. Sawdust, in particular, is an excellent feedstock for charcoal production due to its high carbon content and low moisture levels. A sawdust charcoal making machine facilitates this conversion process by subjecting the sawdust to high temperatures in a controlled environment. The result is a high-quality charcoal that can be used as a fuel source or soil amendment.

Agriculture Waste: A Valuable Resource

Agriculture waste, such as crop residues, straw, and husks, represents a significant portion of biomass available for pyrolysis. For instance, rice hulls, a common agricultural byproduct, are often considered waste but have high potential for conversion into valuable products. The rice hull carbonizer is specifically designed to process rice hulls into charcoal, leveraging their high silica content to produce a unique form of biochar with distinct properties.

The transformation of agriculture waste into charcoal through pyrolysis offers numerous benefits. It reduces the volume of waste that would otherwise be burned or landfilled, thereby mitigating environmental pollution. Additionally, the biochar produced from agriculture waste can be used to improve soil fertility and sequester carbon, contributing to climate change mitigation.

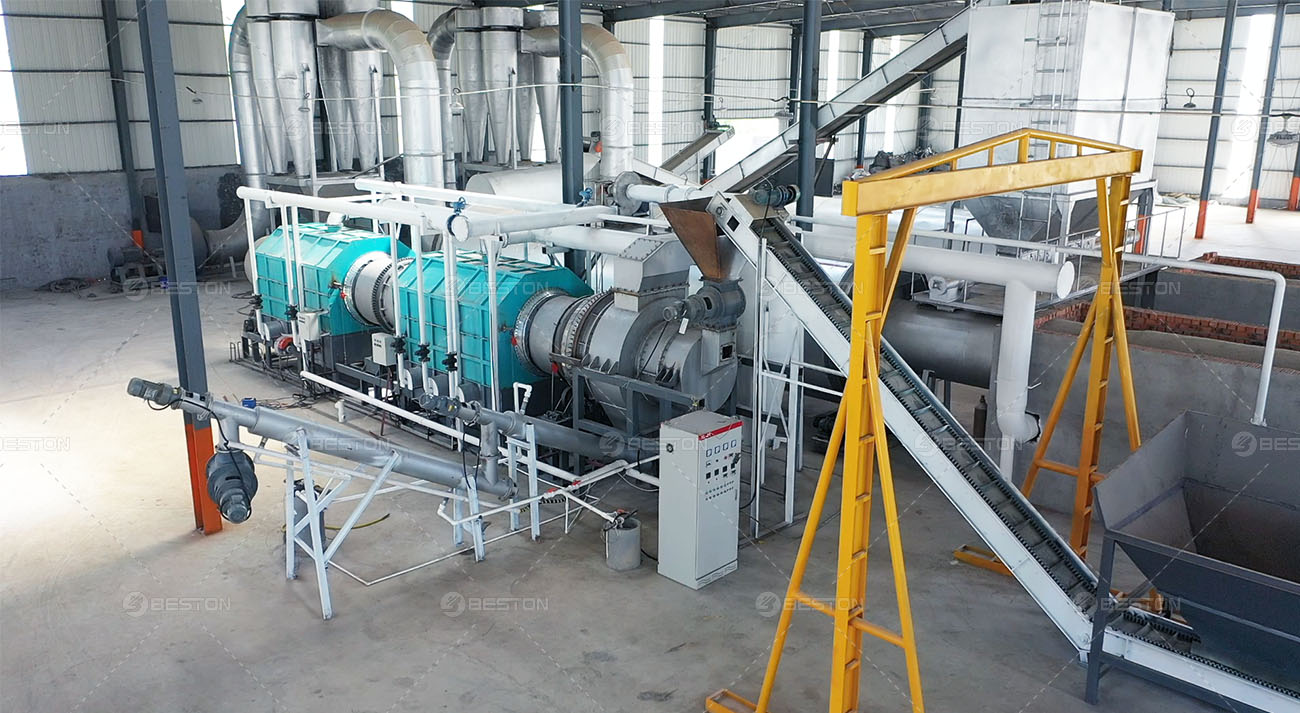

The Role of Pyrolysis Equipment

The efficiency and effectiveness of the pyrolysis process are greatly influenced by the type of equipment used. Various machines are designed to handle different types of biomass and produce charcoal with specific characteristics.

- Sawdust Charcoal Making Machine: This equipment is tailored for the processing of sawdust and other small wood particles. It ensures consistent heating and effective conversion of sawdust into high-quality charcoal.

- Coconut Charcoal Making Machine: Specialized for the conversion of coconut shells, this machine utilizes pyrolysis technology to produce charcoal that is often used in water filtration and as a fuel source.

- Rice Hull Carbonizer: Specifically designed for rice hulls, this equipment addresses the unique properties of rice hulls, including their high silica content. The resulting biochar has applications in soil enhancement and as a filtration medium.

Applications of Pyrolytic Charcoal

The charcoal produced from pyrolysis has diverse applications across various sectors. In the energy sector, it serves as a clean and efficient fuel source with high energy density. In agriculture, biochar enhances soil health and fertility, making it a valuable amendment for sustainable farming practices.

Moreover, pyrolytic charcoal has industrial applications, including use in filtration systems, where its porous structure effectively adsorbs contaminants. Its environmental benefits also extend to carbon sequestration, as the stable carbon in biochar remains locked in the soil for extended periods, reducing atmospheric CO2 levels.

Conclusion

Pyrolysis technology stands out as a transformative solution for waste biomass management, turning wood processing waste, food processing waste, and agriculture waste into valuable charcoal. The process not only addresses waste disposal challenges but also contributes to sustainable energy and environmental solutions. By utilizing advanced pyrolysis equipment, such as the sawdust charcoal making machine, coconut charcoal making machine, and rice hull carbonizer, the potential of biomass as a resource is fully realized. As the demand for sustainable practices grows, the role of pyrolysis in converting waste to charcoal will continue to be a critical component of a more sustainable future.