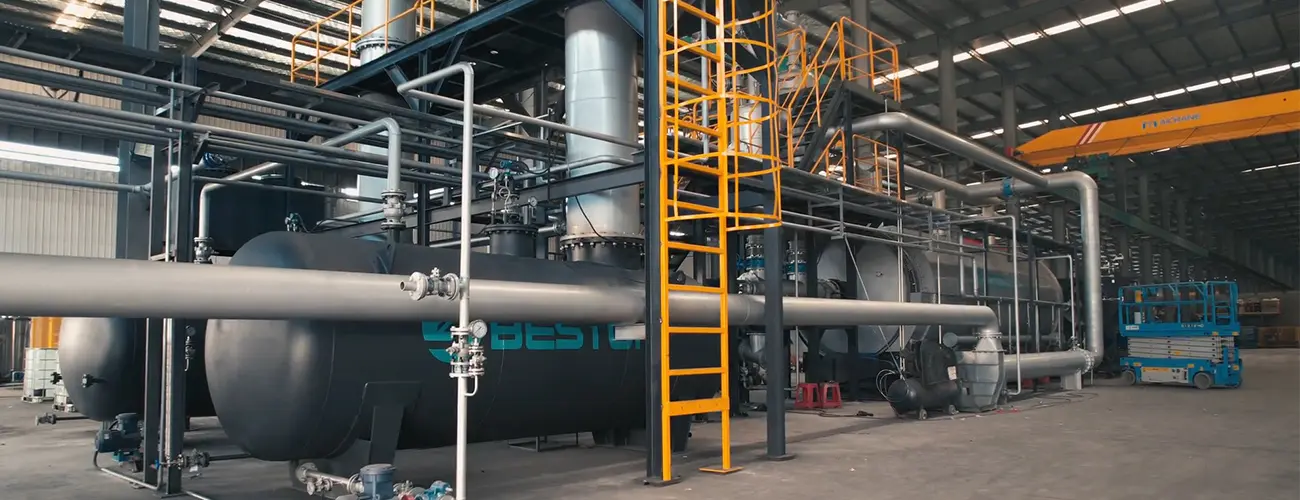

Pyrolysis technology serves as a bridge between waste management and energy production, converting complex hydrocarbons into valuable fuels, gases, and carbon solids. The efficiency and quality of outputs from systems such as the Beston pyrolysis plant are largely determined by the composition of the input materials. Selecting the right feedstock ensures process stability, maximized yield, and superior fuel characteristics. Across industrial applications, the most common feedstocks include waste tires, plastics, biomass residues, and oil sludge—each offering distinctive conversion dynamics and economic value.

Waste Tires

End-of-life tires remain one of the most abundant and energy-dense feedstocks for pyrolysis. Their inherent carbon structure and embedded hydrocarbons enable high yields of liquid oil and solid carbon black. Within a tire to oil plant, the rubber undergoes thermal decomposition, producing pyrolysis oil suitable for fuel substitution and steel wire that can be recovered for recycling. The process simultaneously addresses the environmental burden of tire accumulation while generating marketable by-products. Moreover, the stable composition of tires ensures consistent reactor performance, making them a preferred raw material for commercial pyrolysis operations.

Plastic Waste

Plastic residues, especially polyolefins such as polyethylene and polypropylene, are highly suitable for pyrolysis due to their hydrocarbon-rich content. These materials can be efficiently processed into liquid fuel and synthetic gas within advanced systems, often at a lower operational temperature than tire-based feedstocks. The growing interest in the plastic to fuel machine price reflects an increasing shift toward scalable solutions for plastic waste valorization. Pyrolytic conversion of mixed plastics helps reduce landfill volumes and recovers substantial energy that would otherwise be lost through conventional incineration. The resulting fuel can be further refined into transportation-grade hydrocarbons, supporting the circular use of petrochemical resources.

Oil Sludge and Industrial Waste

Oil sludge and similar hydrocarbon-laden residues are gaining traction as alternative feedstocks due to their high energy potential. When processed in a thermal desorption unit (TDU), these viscous materials release trapped hydrocarbons under controlled heat, producing recoverable pyrolysis oil. The integration of TDU technology within pyrolysis operations allows safe handling of contaminated waste while ensuring resource recovery. This combination enhances the economic and environmental viability of oil waste treatment, particularly in petrochemical and refinery sectors.

Biomass and Agricultural Residues

Organic biomass—such as wood chips, coconut shells, rice husks, and palm residues—represents another essential category of feedstock. These materials produce biochar, bio-oil, and syngas through controlled pyrolysis. Unlike fossil-based feedstocks, biomass contributes to carbon sequestration and soil enrichment when converted into biochar. The process design of the Beston pyrolysis plant allows flexibility to handle such fibrous and moisture-variable inputs through pre-drying and heat recovery systems. In rural or agro-industrial contexts, biomass conversion provides both energy and waste management benefits, aligning with sustainable production goals.

Optimizing Feedstock Utilization

The versatility of modern pyrolysis systems lies in their adaptability to diverse feedstocks. Whether processing tires, plastics, biomass, or sludge, high-grade equipment ensures efficient thermal transfer, gas recirculation, and emission control. The selection of feedstock should balance availability, energy density, and market demand for end products. With technological advancements and declining equipment costs, including competitive plastic to fuel machine price points, pyrolysis continues to emerge as a cornerstone of sustainable waste-to-energy conversion.