How much do you know about the cost of owning and operating a tyre pyrolysis plant? Are you aware what sets a particular model apart from others? Do you understand the factors that really matter when it comes to success in this business? In this article, we will discuss the overall cost of establishing a completely new tyre pyrolysis plant and what you should do in order to set up your business for long-term success.

Type of Plant

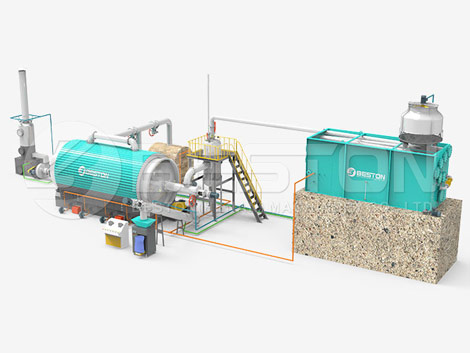

Not many people are aware of the fact that pyrolysis plants are available in many types. Even though the underlying technology or underlying principle works in the same manner, there are quite a few differences between different types of plants. For instance, there are portable plants that can be driven to the location and process various types of raw materials.

Similarly, there are stationary plants that utilize this technology for processing of tires as well as other types of materials. In addition, there are pyrolysis plants that are designed to process a variety of raw materials and not just waste tyres. This is why, the cost depends on the type of plant you choose. In most cases, you can buy a starting plant in the price range of around $50,000. However, you can buy continuous pyrolysis plant for upwards of more money.

Automation Level

The cost also depends on the level of automation. A fully automated plant will obviously cost a lot more money as compared to a semi-automatic or a manual option. However, the higher cost does offer several advantages. You will, obviously, save money on labor. Another advantage of fully automatic plants is that you can operate them continuously without worrying too much.

Plant Capacity

Processing capacity of the waste tyre to oil plant also affects its cost. Needless to say, you would have to pay more for bigger processing capacity. You need to choose the processing capacity carefully. Buying as much capacity as you can afford to buy is not the right way to set up this business. If you’re not able to use the established capacity, it will eat into your margins and you might not remain competitive in the market. This is why, carefully researching market to figure out the demand for products as well as availability of raw materials before choosing a particular capacity is the right way to do things.

Quality of Materials

The quality of materials used for making various components also affects the cost of pyrolysis plant. Higher quality materials cost more money. In addition, you will also need to pay a premium for better design. A better designed plant is more efficient as compared to designs that were created in the late part of the 20th century. Similarly, modern designs come equipped with a number of exceptional features that help in enhancing efficiency and implementing operator errors. A plant made from high quality materials will last much longer and break down much less frequently as compared to plants made of lower quality materials and that would obviously add to the cost.

Overall, a number of factors affect the final cost of a waste tyre recycling plant including the quality of materials, capacity of the plant, level of automation as well as the type of plant. You should carefully research the market in order to figure out the demand as well as supply of raw materials in order to choose the right pyrolysis machine.