In the labyrinth of environmental challenges, the concept of transforming discarded plastic into a valuable resource has gained substantial traction. This phenomenon, often referred to as the plastic to oil solution, represents a compelling avenue in the pursuit of sustainable waste management. Let’s embark on a journey to unravel the intricacies of this innovative approach.

Plastic Predicament: A Global Quandary

Plastic waste, an omnipresent adversary in our daily lives, has reached staggering proportions globally. Conventional disposal methods have proven inadequate, fostering a burgeoning environmental crisis. It is against this backdrop that the plastic to oil plant emerges as a potential game-changer.

Understanding the Alchemy: Plastic to Oil Conversion Process

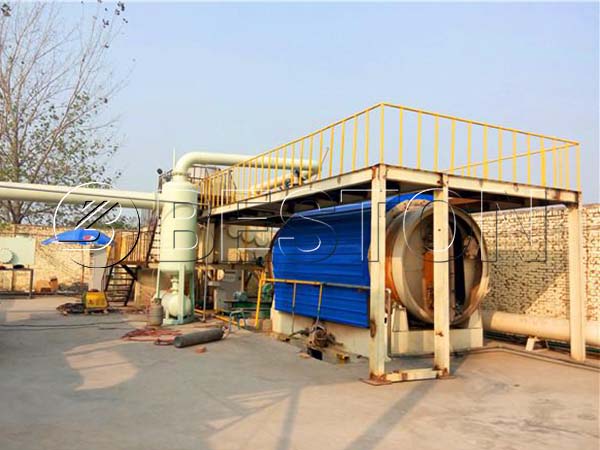

The heart of this transformative process lies in a methodological alchemy known as pyrolysis. Pyrolysis, a thermal decomposition technique, subjects non-recyclable plastic to controlled heat in the absence of oxygen. This intricate dance of temperature and absence triggers a molecular metamorphosis, converting plastic into a stream of hydrocarbon vapors.

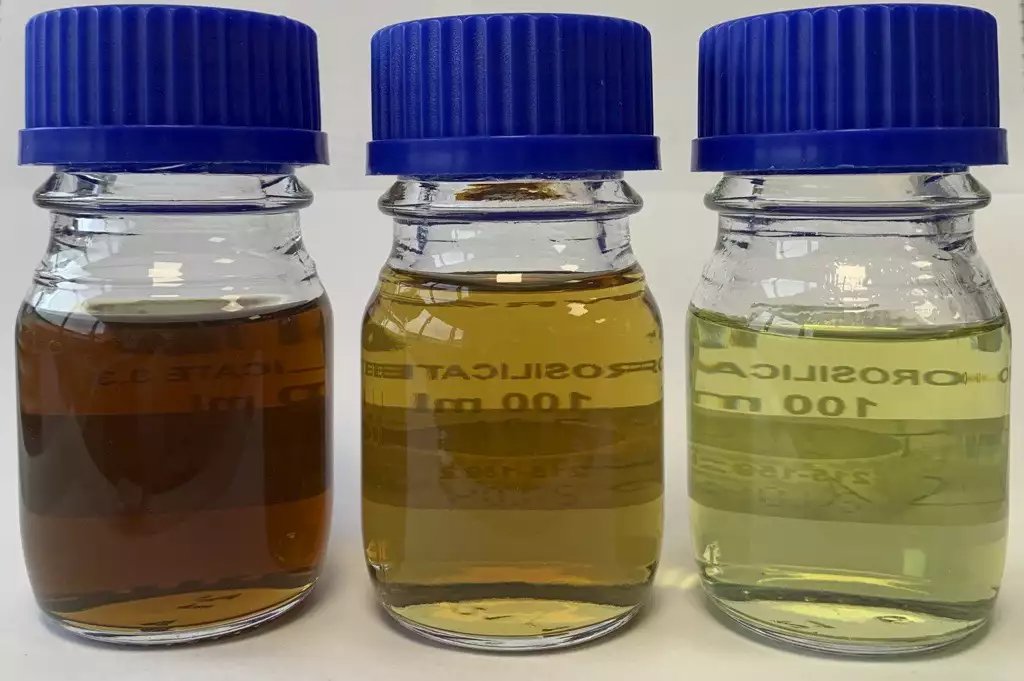

The process of pyrolysis plant dismantles the complex polymer chains of plastic, giving rise to a spectrum of outputs. The most coveted among them is the liquid fraction, aptly named pyrolysis oil. This liquid elixir holds the promise of versatility, serving as a precursor for various applications.

Liquid Elixir: Applications and Versatility

The resulting pyrolysis oil is not a singular entity; rather, it is a versatile substance with applications that transcend conventional expectations. Its primary role lies in fuel production, where, through refining processes, it metamorphoses into a range of fuels, from diesel to gasoline.

Yet, the liquid elixir’s utility extends beyond the energy sector. It finds resonance in petrochemical industries, acting as a feedstock for the synthesis of diverse chemical compounds. This underscores the plastic to oil solution’s potential to contribute holistically to industrial processes.

Economic Dynamics: Plastic to Oil as a Resource

A critical facet of evaluating any sustainable solution lies in its economic viability. The plastic to fuel machine not only addresses the mounting issue of waste management but also presents an opportunity for economic valorization. As technology advances, the costs associated with pyrolysis decrease, amplifying the competitiveness of this approach in the waste-to-energy landscape.

Environmental Impact: Disrupting the Linear Flow

From an environmental standpoint, the plastic to oil solution disrupts the linear trajectory of plastic waste, diverting it from conventional disposal methods. By doing so, it pioneers a circular paradigm where non-recyclable plastics transform into a valuable resource, contributing to the broader ethos of sustainability.

Challenges and Future Trajectory

Despite the promise, challenges persist on the road to mainstream adoption. Technological advancements are imperative to enhance the efficiency of the pyrolysis process and accommodate the diverse spectrum of plastic compositions. Simultaneously, a robust regulatory framework is essential to ensure responsible deployment and mitigate potential environmental repercussions.

Conclusion: A Transformative Odyssey

In conclusion, the oil from plastic machine stands at the crossroads of innovation and environmental responsibility. The alchemical transformation from plastic to a liquid resource not only addresses the plastic predicament but also signifies a testament to human ingenuity in the face of pressing challenges. As the journey from plastic to oil continues to evolve, it beckons us toward a future where waste is not merely a burden but a wellspring of possibilities.