If you only have a small amount of waste plastic to process every day, a pyrolysis plant might be able to satisfy your needs. The great thing about small plants is that they take up less floor space and can be more fuel-efficient for processing small amounts (less than 6 tons) of plastic waste each day. You will find reliable pyrolysis machine for sale. Such machines utilize bath-type pyrolysis technology to reduce area requirements and reactor energy consumption.

Most small-scale plastic pyrolysis plants adopt a batch working method rather than a semi-continuous or continuous working method. This means that waste plastic materials are processed in batches and the reactor has to be cooled down between batches. The cool down is required to remove slag from the chamber.

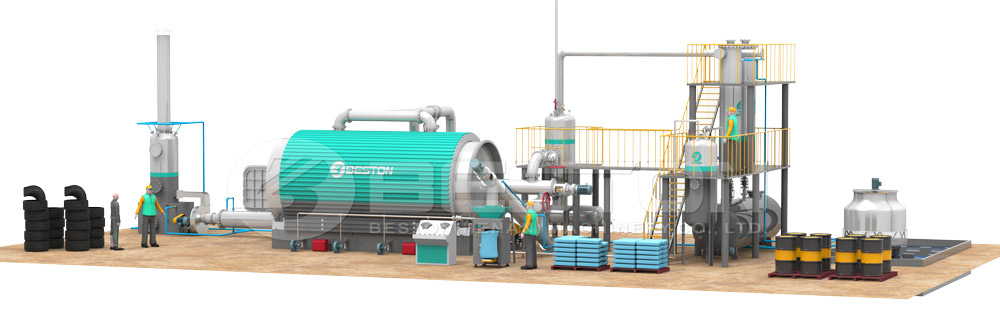

Now let’s talk about some of the typical data specifications of a Beston Machinery pyrolysis machine. In terms of daily capacity, around 6 tons of waste can be converted into fuel oil each day. The reactor has a length of 6 meters and a 2.2-meter diameter. The pattern of the reactor is both horizontal and rotary. Total power requirements for the reactor are 24 kW/h and a range of heating materials can be used, including LPG, natural gas, wood, charcoal, etc.

In addition to processing plastic waste, a mini pyrolysis machine can also process medical waste, oil sludge, rubber, road tires and much more. The condensing system of the machine relies on water cooling technology and the average service life of the reactor is seven years. The total flow area requirement for installation is 30 meters by 10 meters by 8 meters (length by width by height).

Pyrolysis plants from the best manufacturers are high-quality, competitively priced, eco-friendly, and durable. You will find dozens of pyrolysis plants for sale online, so buyer research is very important. If you run a business in Europe, it’s vital that you look for plastic recycling machines that meet EU environmental protection emission standards. This means you need to look at the flue gas discharging specs of different pyrolysis plants.

The most profitable end product output from a small scale pyrolysis unit is pyrolysis oil. With a crude oil refinery machine, it is possible to turn that oil into high-quality diesel. The oil yield of a plastic pyrolysis various based on the type of plastic. PVC and PE, for example, have oil yields exceeding 90%, while ABS plastic has an oil yield of just 40%.