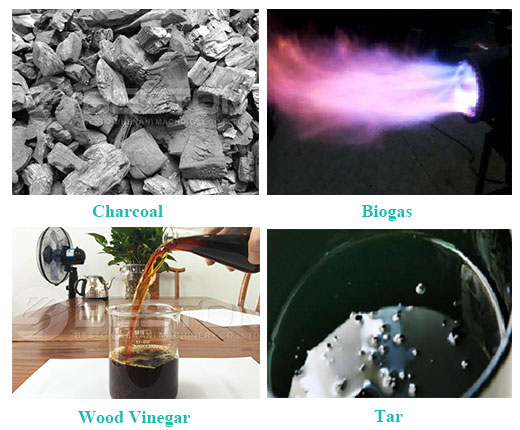

Biomass pyrolysis plant can be defined as the process in which biomass is converted into charcoal, vinegar, biogas, and tar through the corbonization process. This process uses high temperature in heating the biomass charcoal. In the advanced technology, the idea of carbonization is employed. All this process is carried out by biochar production equipment; this machine has become widely accepted in the market. From the final products that are produced, biomass charcoal is the main product. The charcoal is rich in carbon and hence can be used as the source of heat energy. The whole process of biomass pyrolysis is an ideal investment that is environmentally friendly.

Raw Materials for Biomass Pyrolysis

The biomass has got many materials like sawdust, wood, coconut shell, palm shell, rice husk, sugarcane bagasse, weeds, and leaves among other waste materials. Most of these raw materials are readily available and are cheap in the market today. With this in mind, it means that there is a little cost invested but the profit is high.

Production Process of Biochar Machine

The whole charcoal making process involves four main stages in which the waste undergoes. This process can be simply referred to them as the high temperature of the pyrolysis of biomass, the smoke discharge, emission of sulfur and the last one is the charcoal enrichment. The process utilizes the high temperatures so that to ensure that the raw materials have generated the required reactions in the carbonization furnace. See the biochar machine here.

The first step involves crushing the raw materials onto a mall piece of around 40 mm and then removes moisture from it. The temp is high to ensure that about 20% of the residual moisture has been removed.

The products from step one are then passed through the conveyor where they are processed to the pyrolysis reactor and heated at a high temperature. They are heated up to the required or maximum temperature. At this temperature combustible gas and charcoal are generated within the furnace. The whole process in this step takes around 15 minutes.

The charcoal is then passed through the cooling system whose temperature is 30. This enables biomass charcoal to be discharged directly. On the other hand, the combustible gas is directed to the condenser and dedusting system in order to remove sulfur, tar, vinegar, and wood. The final stage is the recycling of the purified combustible gas onto the furnace. This process is safe to the environment since there is pollution agent that is released to the environment.

How to Achieve Biomass Pyrolysis Process

The initial temperature should be maintained to ensure that it has reached the required one so as to begin the pyrolysis process. In order to ensure you have reached this, you need to pre-heat the reactor for around 30 minutes before you take off the process. Convey the raw materials of 40 mm to the carbonizing furnace. You can use the belt conveys and forklift to achieve this. Ensure that the combustible gas has been directed onto the condenser for purification in order to get the other end product.

Advantages of Biomass Pyrolysis Plant

· There is temperature control within the whole system. There are many water cooling channels within the machine so that to ensure that the required temperature has been maintained.

· Environmental friendlily and protection- The machine is sealed and configured in order to make sure that the small charcoal making machine is safe and clean to the environment.

· The machine effectively uses the high heat required for its working. It is the double layer made to ensure that the lower part has adopted the hot heat as possible.

· Its design is very secure to operators and to the environment. It is sealed and configured to ensure that the heat is not contacting the body directly.

Conclusion

Biomass pyrolysis plant is ideal and its working is of high quality that can be accepted by anybody. With our services of producing carbonized charcoal cannot be regretted in any way. We have the required s experience that you may need in this field. Investing in biomass charcoal is something that you are sure you are going to get profit. Please do not hesitate if at all you are planning to invest in charcoal making machine. The raw materials that you need for production are readily available and cheap.