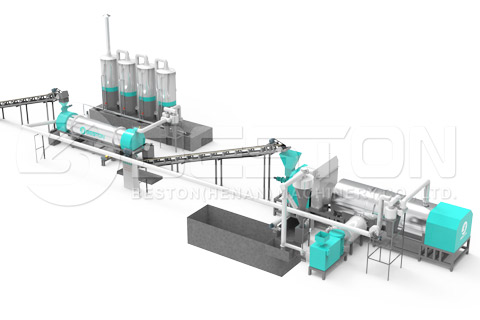

Some of the top-rated coconut shell charcoal making machine manufacturers are Beston Machinery. In this blog post, we are going to be talking about bio charcoal making machines from Beston Group. The coconut shell charcoal making machine manufacturers are known for integrating exceptional research, development, design, engineering, production and customer services into all of their biochar machines.

Buyers from just about every continent on the plant have sought machinery from Beston.

Some of the places the company has exported machinery to include the UK, South Africa, Indonesia, South Korea, Australia, Russia and more. Biomass waste charcoal plants from the manufacturer have many benefits, such as reliable performance, first-class manufacturing processes, unique design concepts, high-quality components, excellent green credentials, and high energy efficiency.

A modern coconut charcoal making machine utilizes intense heat and oxygen-absent carbonization technology to convert waste biomass materials into biochar, biogas and several other valuable byproducts. The best thing about modern machines is that they produce zero pollution during operation as long as a clean fuel source is used to power the biochar machine for sale.

In addition to being able to process coconut shell waste, the latest biochar making machines can also process many other forms of biomass waste, including bamboo, olive shell, rice husk, sewage sludge, wood, sawdust, palm kernel shells, municipal solid waste, agricultural waste and much more. All of those aforementioned biomass waste materials can be converted into clean-burning, high-calorie charcoal fuel briquettes with the right equipment. Unlike other types of fuel briquettes, biochar briquettes produce little smoke and have high thermal energy potential, making them ideal for use with BBQs and other outdoor cooking equipment.

Another main use for coconut shell charcoal is in soil improvement formulas. The material can not only improve soil aeration and drainage properties, but it can also add crop yield boosting micronutrients to the soil. Furthermore, biochar has great antifungal and antimicrobial characteristics, so it can help to reduce outbreaks of root diseases in crops. Check the biochar production equipment here.

maximum hourly feeding capacity of 3 tons and can process all manner of biomass waste. The machine utilizes recycled waster cooling technology and has an average life span of around 7 years. The total power output of the machine is 72 kW/h and the reactor can be fuelled by many different heating materials, such as diesel, LPG, charcoal, natural gas, wood, etc.

Beston Group coconut shell charcoal making machines come with integrated drying systems, which ensure the moisture content of raw materials is below 18% before they enter the reactor. This guarantees efficient carbonization processes. If the moisture content of coconut shells is above 20%, too much steam will be produced in the reaction furnace for effective carbonization.

You can learn more about the working operations of Beston Group’s charcoal machines on the company’s official site. You can also request a price estimate for a customized design from the coconut shell charcoal machine manufacturers.