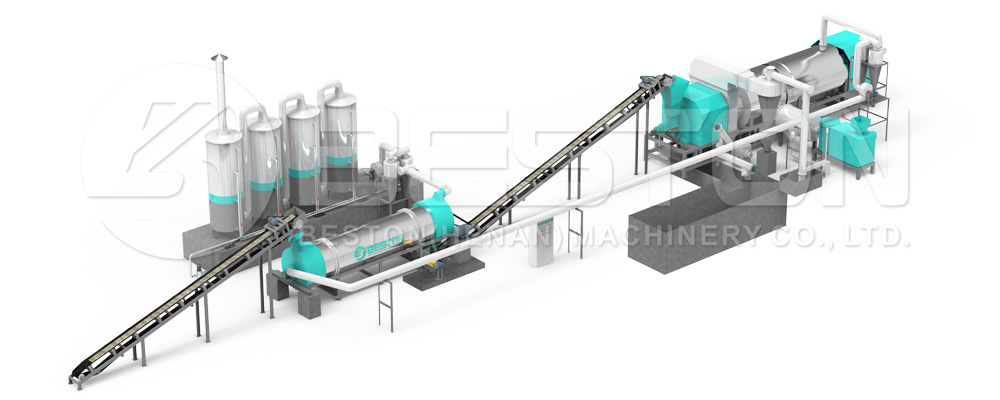

Biochar production equipment is used to convert all forms of biomass waste into useful commodities without further polluting the atmosphere. It relies on carbonization processes and can help regions to effectively recycle mounting agricultural waste, such as wood chips, palm shells, straw, sawdust, and rice hulls. The final products reclaimed from various types of agricultural waste may include wood vinegar and tar in addition to biomass charcoal. See the high-performance biochar production equipment here.

The biomass charcoal produced is both an excellent clean-burning fuel and a great soil enhancer. It burns cleanly as it contains over 95% carbon. Consequently, one of its applications is as a fuel source for outdoor cooking equipment. The reason biomass charcoal is a great soil enhancer is that it has great antifungal and antimicrobial properties that help protect plant roots from various diseases. It’s also nutrient-dense, so is often able to increase crop yields tenfold depending on the crop variant.

The biomass charcoal reclaimed from agricultural waste using biochar production equipment can also be put through further processing and turned into activated carbon. Activated carbon has a wide range of applications and is sought-after by metal refineries and the chemical, pharmaceutical, and water treatment industries. The by-products produced during biomass charcoal production have their own unique applications and are easy to profit from in the open marketplace. Click here to know more: https://bestonpyrolysisplant.com/.

So, how does biochar production equipment work? To begin with, the moisture content of the unprocessed agricultural waste must be under 20% for optimal carbonization. Waste with high moisture contents can often be dried automatically using and leaked heat from the main carbonization furnace. After pretreatments (including drying and crushing), the agricultural waste is transferred to the carbonization furnace where it is heated to an extremely high temperature in an oxygen-free zone. Instead of burning and smoking, the waste carbonizes, and combustible gas vapor is produced.

Biochar production is an environmentally friendly process and all modern plant equipment is designed for maximum energy efficiency. In batch plants, the furnace must be cooled down between batches so the charcoal can be collected. In continuous biomass carbonization plants, no cooldown is necessary between batches as such plants are fitted with automatic discharge and collection systems.

Beston manufacturers a range of biomass carbonization plants. One of its top models can process up to three tons of agricultural waste each hour. The life expectancy of a plant from Beston is between 5 and 8 years depending on the surrounding environmental conditions and daily processing pressure. The good news is that the manufacturer provides great after-sales services and can provide customers with customized plant configurations built to their unique specifications. The manufacturer has years of experience serving both domestic and international customers. It’s unlikely that you will be able to find a biomass carbonization machine from another manufacturer that is as competitively priced or durably built as Beston’s biochar production equipment. Get a reasonable rice hull charcoal machine price here.